Projects and research

Our commitment to applying knowledge

At MaintLAB, we work daily to transfer the latest knowledge from the field of technical maintenance to concrete industrial challenges. Through cooperation with partners from business and the scientific community, we develop solutions that improve maintenance processes, reduce costs and increase equipment reliability.

Scientific research projects

Our research efforts are focused on the application of artificial intelligence, machine data processing and IoT technologies in predictive maintenance

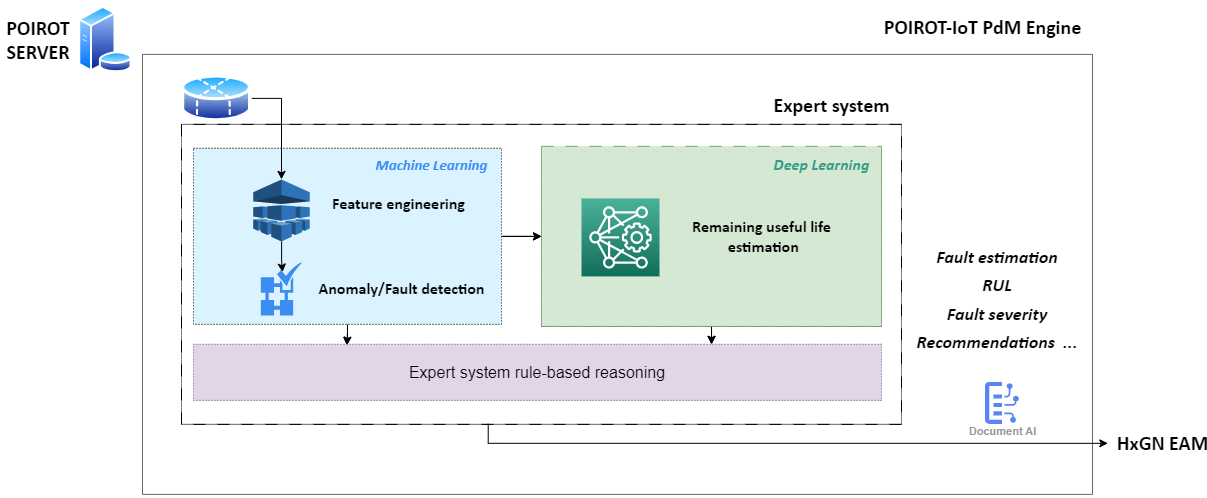

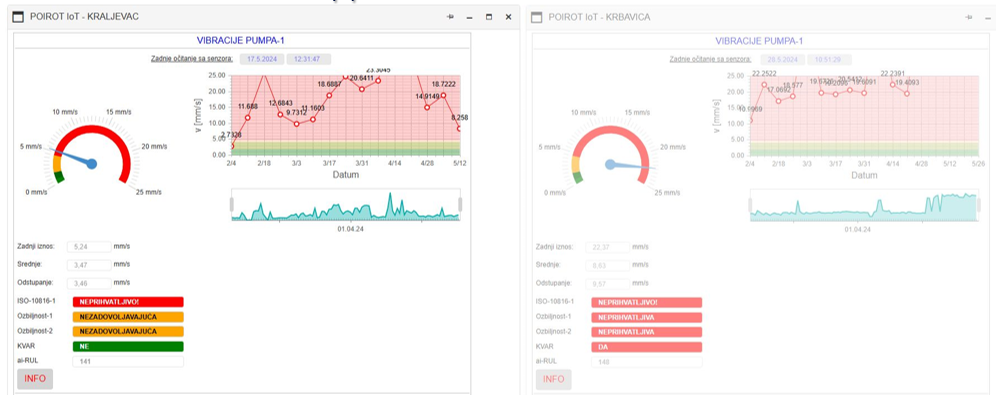

POIROT-IOT: Converting maintenance data to knowledge

Predictive maintenance of industrial rotating equipment based on machine learning and IoT technology in interaction with information systems

- Main partners: UniZG FSB, Ekonerg d.o.o.

- Project value 1.2 million E

- Over 20 participants

- Results: 1 patent application, 8 scientific papers, 10 presentations at conferences

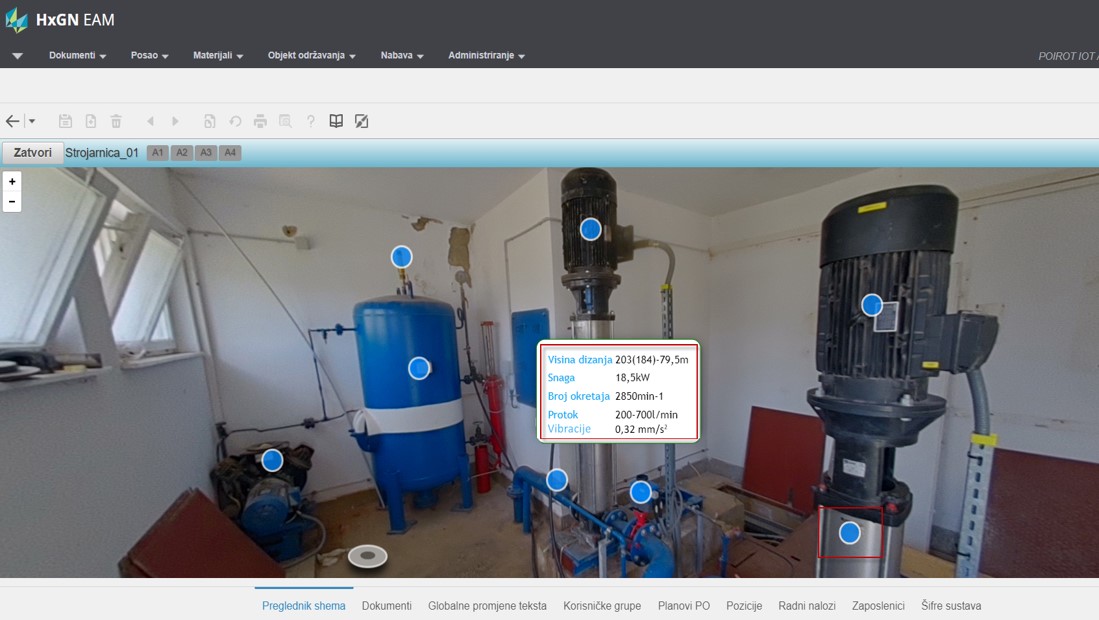

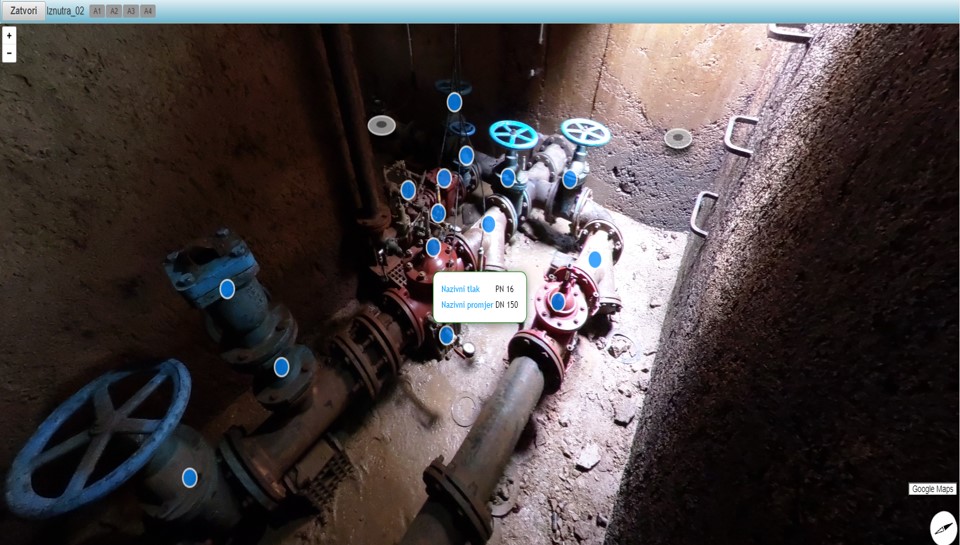

Data access and integration with existing systems

Upgrading an existing SCADA system

Digitalization of processes through the EAM system

Development of communication and data collection modules

Data integration via a centralized storage system

Improved maintenance decision-making with artificial intelligence

Implementing a predictive maintenance (PdM) framework using artificial intelligence

Integration with EAM system

Visualization and decision support module

Professional projects

In collaboration with leading industry partners, we have developed and implemented a range of advanced systems and solutions.

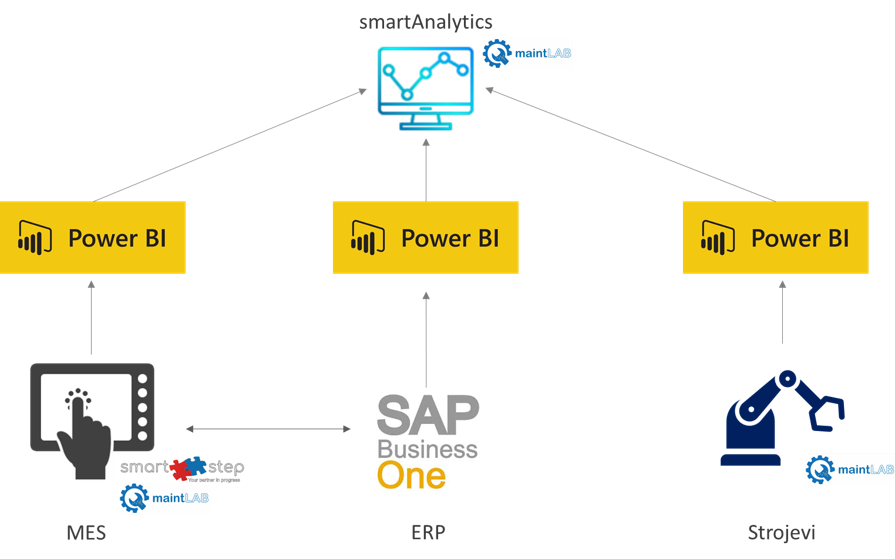

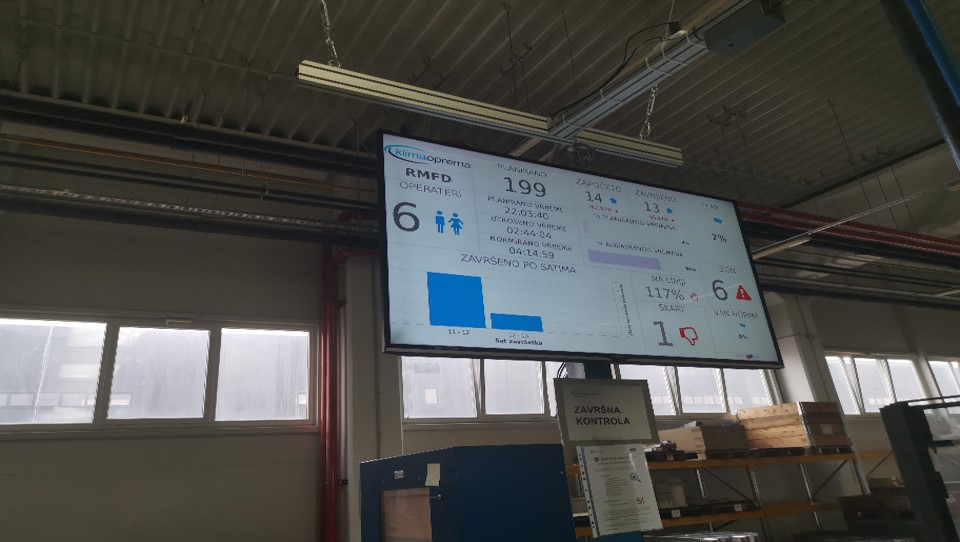

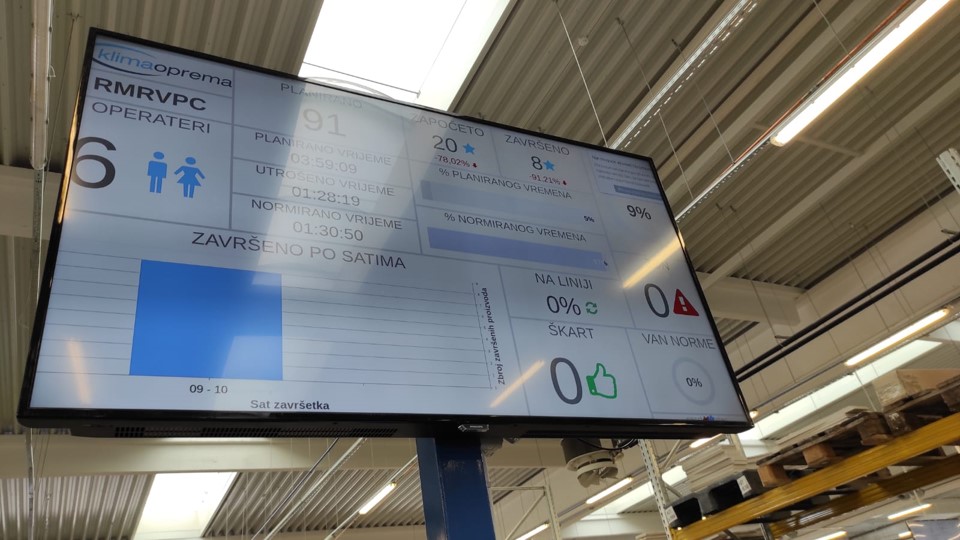

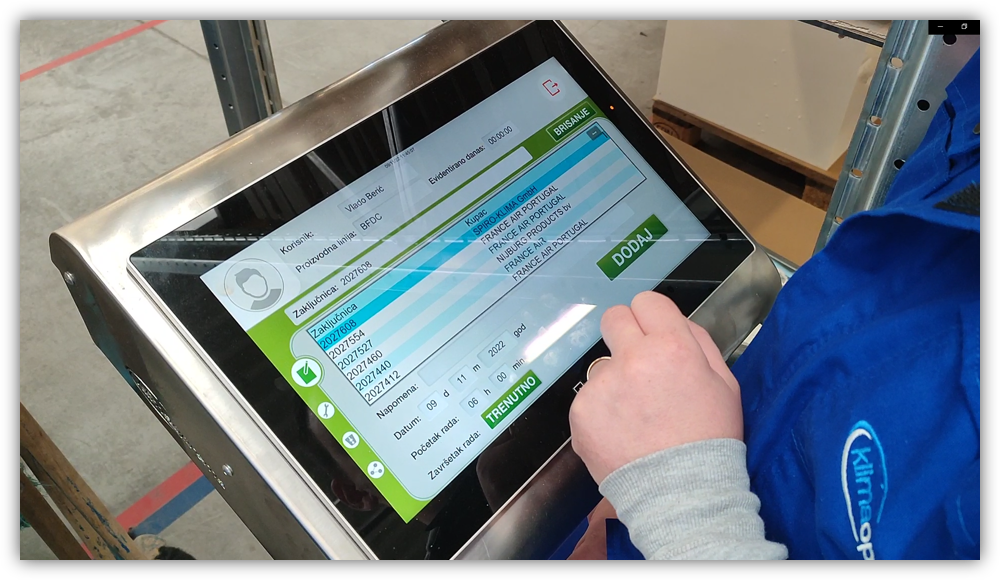

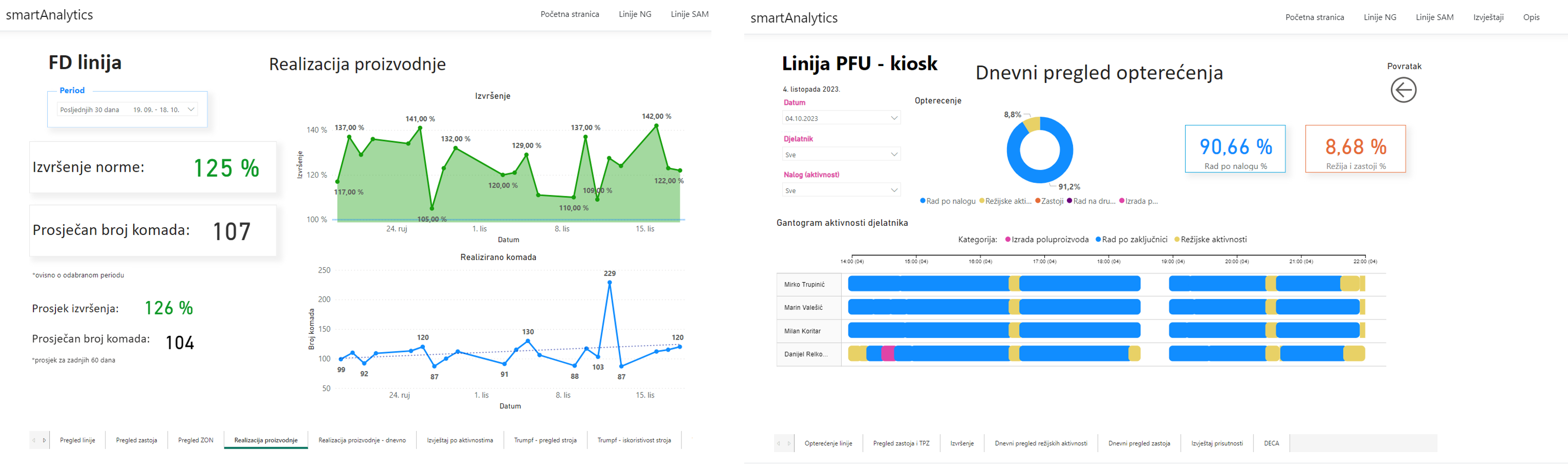

Digitalization of the production recording system (MES)

Digitalization of work record systems on production lines

- Introduction of terminals in production

- Internal software development

- Development of a centralized reporting system

- Results: real-time work record

System architecture