Research equipment

State-of-the-art equipment and devices for monitoring and analysis

To support research, industrial collaboration and education in the field of technical maintenance, MaintLAB has modern diagnostic and experimental equipment. Our laboratory infrastructure enables precise monitoring of the condition of industrial systems, development and testing of advanced algorithms for predictive maintenance and implementation of IoT solutions in real industrial conditions. Below we present the key devices that form the technical backbone of the laboratory.

Industrial equipment

BTS-P 3000 – Forecast simulator

- Laboratory system for testing and accelerated degradation of bearings.

- Allows installation of multiple bearing sizes (Ø30, Ø35, Ø40 mm).

- It is controlled by dynamic and static load (hand hydraulic and vibration motor).

- It is used to develop and validate algorithms for predictive maintenance.

MFS Expert – Rotary Equipment Failure Simulator

- Training device for simulating mechanical failures of rotary systems.

- It enables education and testing of condition monitoring methods.

- Integration with diagnostic equipment (vibration, ultrasound).

SDT Vigilant – Continuous Equipment Monitoring System

- Industrial IoT device for permanent monitoring of equipment condition.

- It enables real-time measurement of vibrations, ultrasound and temperature.

- It connects to cloud solutions or local databases.

SDT 340 – Portable condition monitoring device

- Advanced ultrasonic analyzer for passive and active monitoring.

- It is used to detect leaks, poor lubrication and mechanical failures.

- It is used in industrial inspections and as field diagnostic equipment.

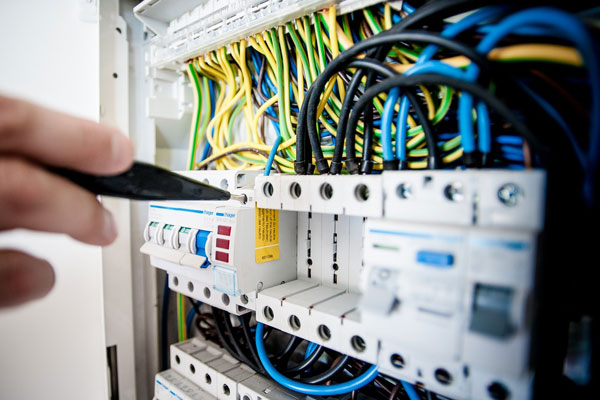

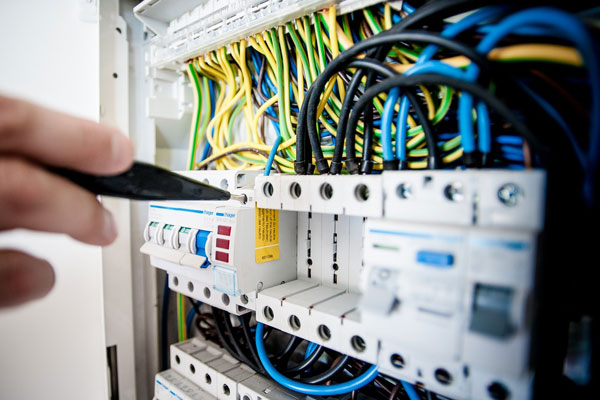

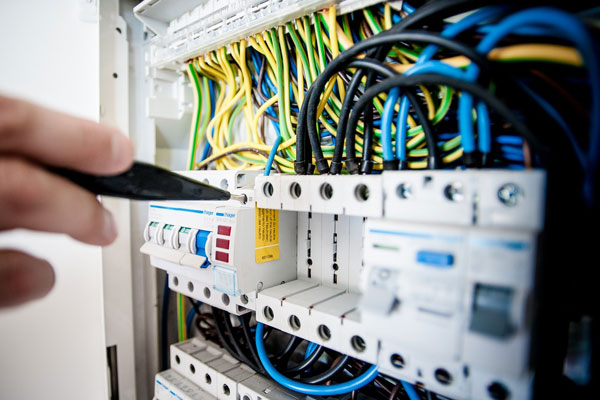

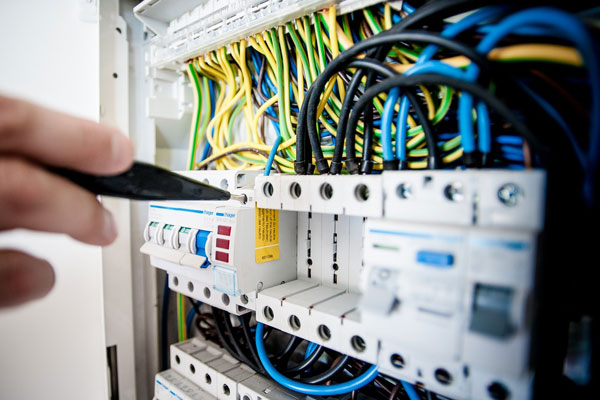

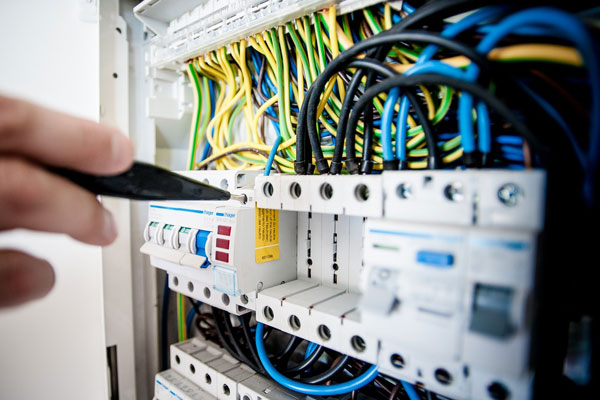

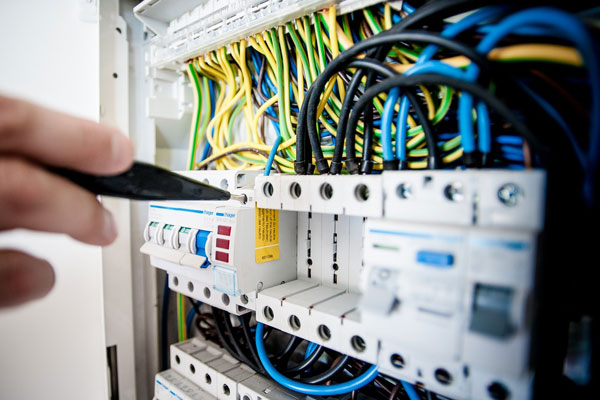

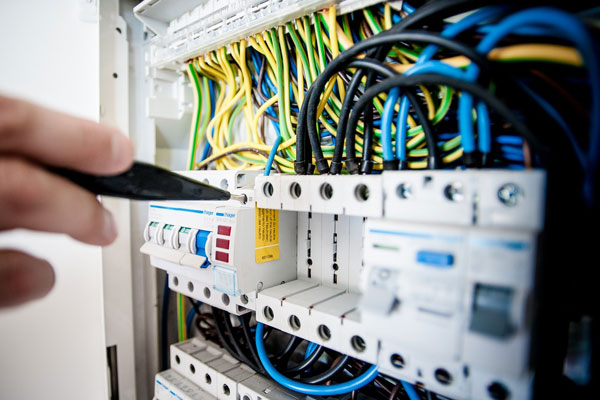

FLIR A315 / FLIR E8 / FLIR TG – Thermal imaging cameras

- Kamere za detekciju toplinskih anomalija u strojevima i električnim instalacijama.

- FLIR A315: integration into automated surveillance systems.

- FLIR E8: mobile inspection in field conditions.

- FLIR TG: compact camera for fast temperature measurement.

smartBox – IoT equipment monitoring system

- An internally developed solution for collecting and visualizing data on the condition of the equipment.

- Measures: vibrations, temperature, infrared radiation, ultrasound, process parameters.

- It supports digital and analog inputs and local or remote data storage.

National Instruments cRIO – Data Acquisition System

- Modular system for real-time acquisition of industrial signals.

- It is used for experimental measurements and the development of predictive diagnostic systems.

- Connectable to the LabVIEW platform and other analytical tools.

Software

Node RED

SDT UltraAnalysis Suite

Microsoft SQL Server

Altair AI Studio